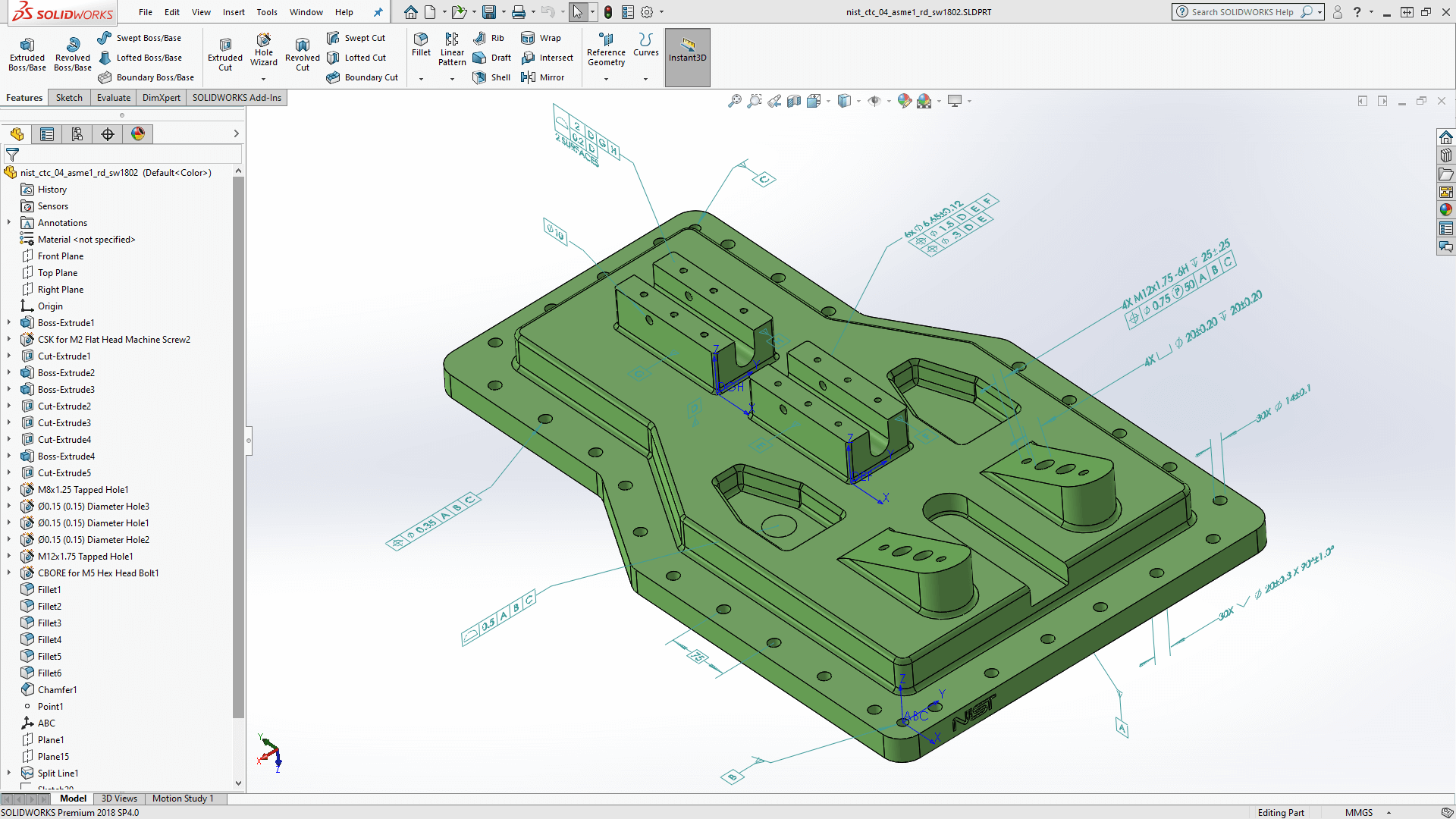

Native CAD plug-in for exporting 3D CAD Neutral File Formats (QIF and STEP AP242)

True Model-Based Definition (MBD) CAD + semantic PMI

that is Human & Machine Readable.

Also Available: MBD Connect for Creo | MBD Connect for NX

Export to QIF and STEP AP242 for multi-CAD, multi-use interoperability.

From CATIA, Creo, NX, QIF, STEP AP242, and more.

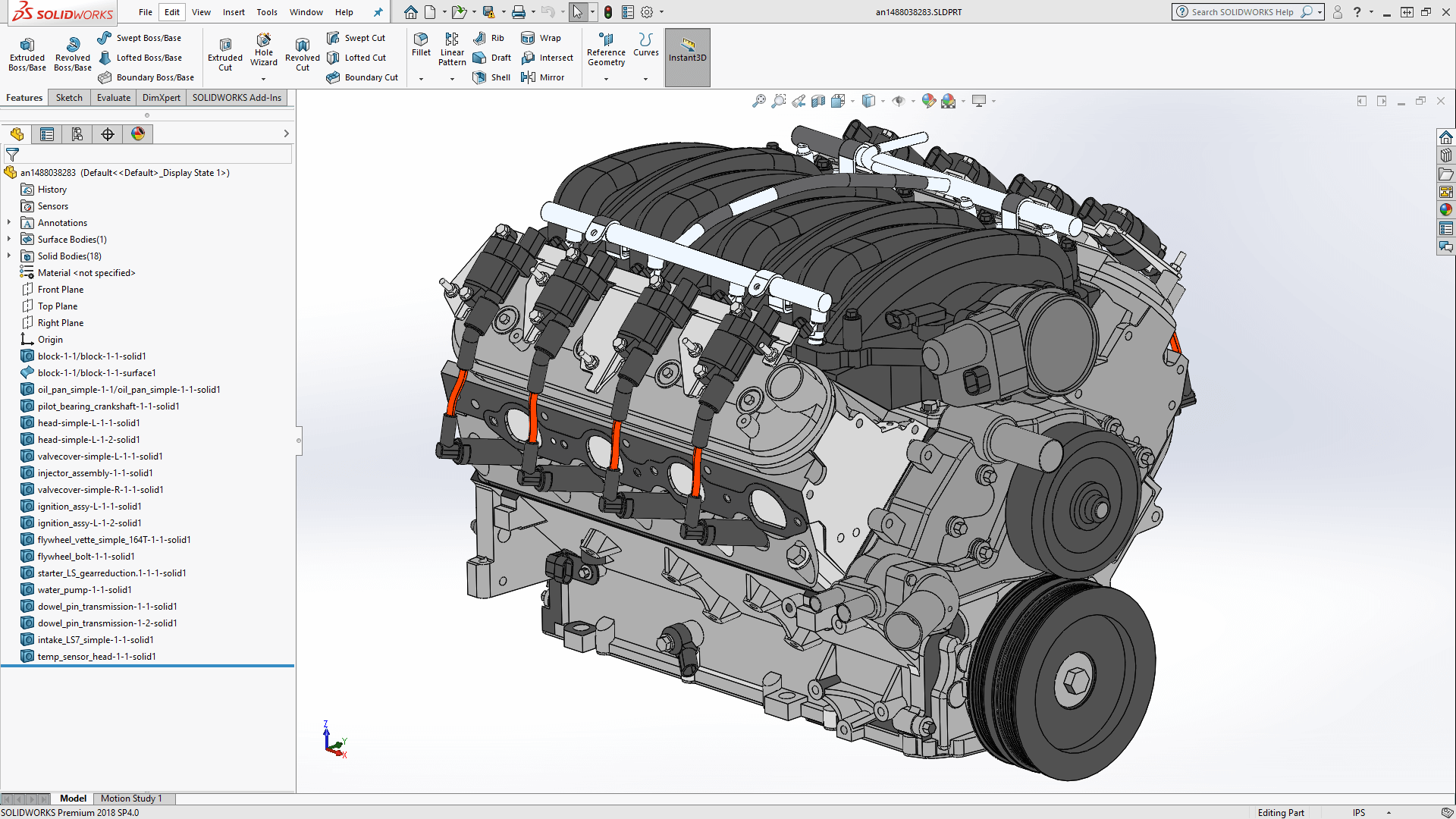

Use MBD CAD data for downstream manufacturing and inspection software.

Publish a QIF or STEP AP242 model directly from SOLIDWORKS.

Multi-CAD interoperability throughout the digital thread and workflow. Compatible with SOLIDWORKS 2018, 2019, and 2020.

From CATIA, Creo, NX, QIF, STEP AP242 and more.

Machine-readable PMI enables downstream processes in manufacturing to quality.

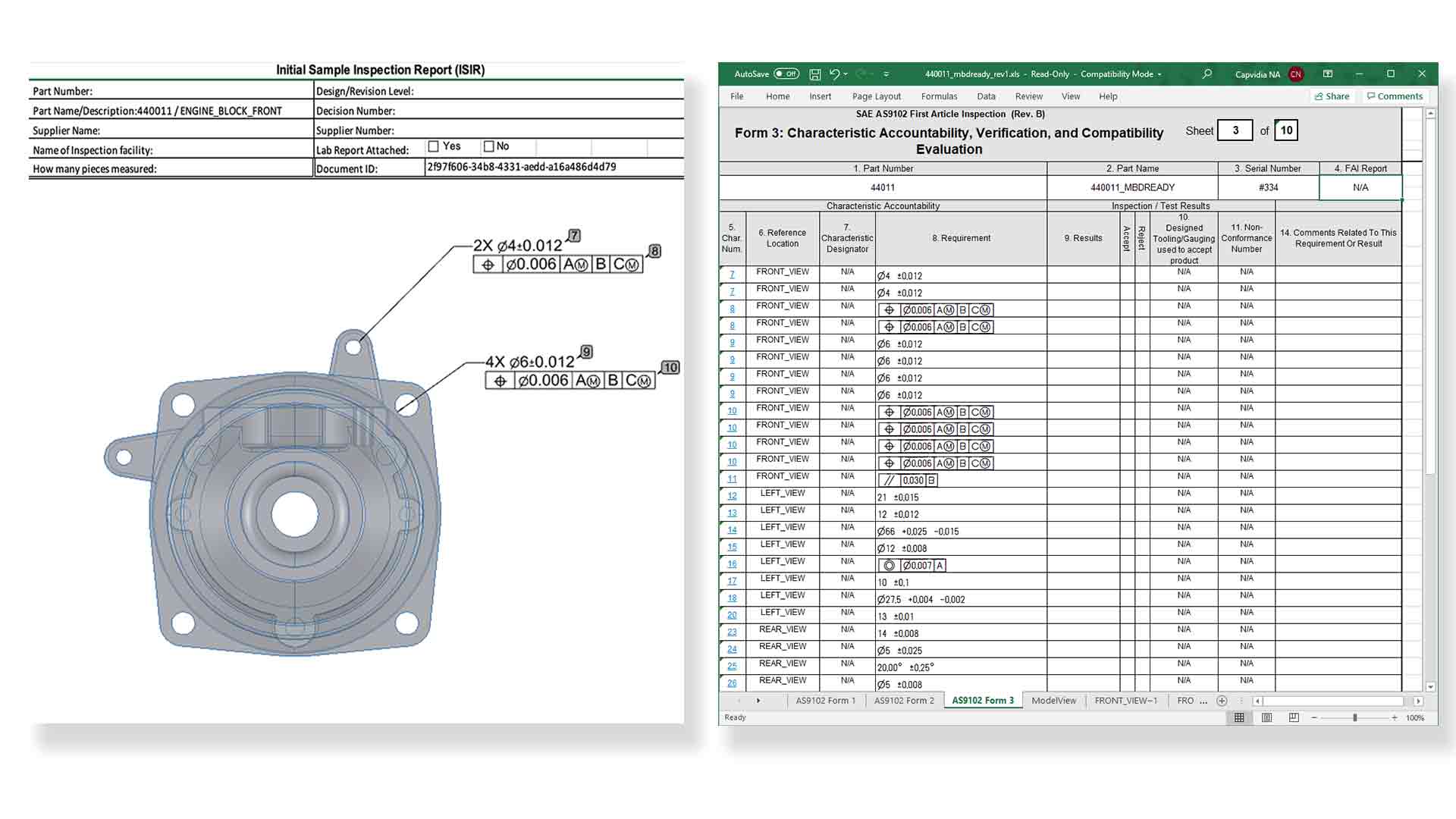

Endless possibilities with MBD: Automated FAI and CMM. Harvest measurement data. Import measurement results back into MBD model for improved product and business insights.

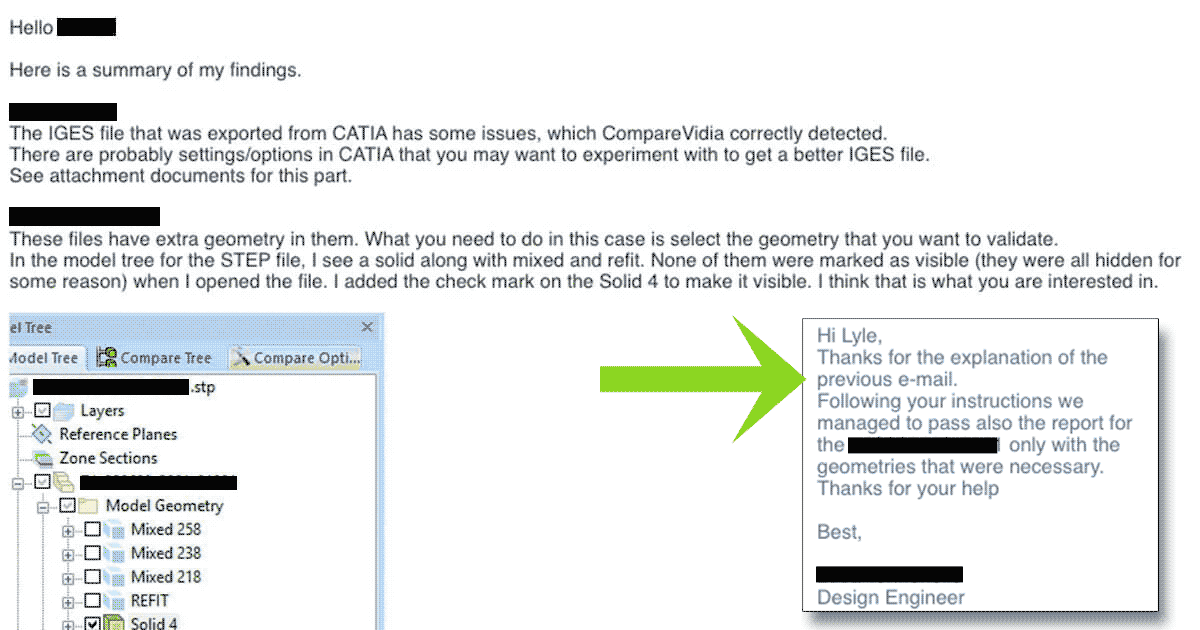

Second to none in personal support. We don't sell software; we provide solutions no matter how big or small.

Rely on an automated, structured process.

Import precious data beyond PASS/FAIL back into MBD.

100% automated workflow with a couple of clicks. Export to Excel easily.

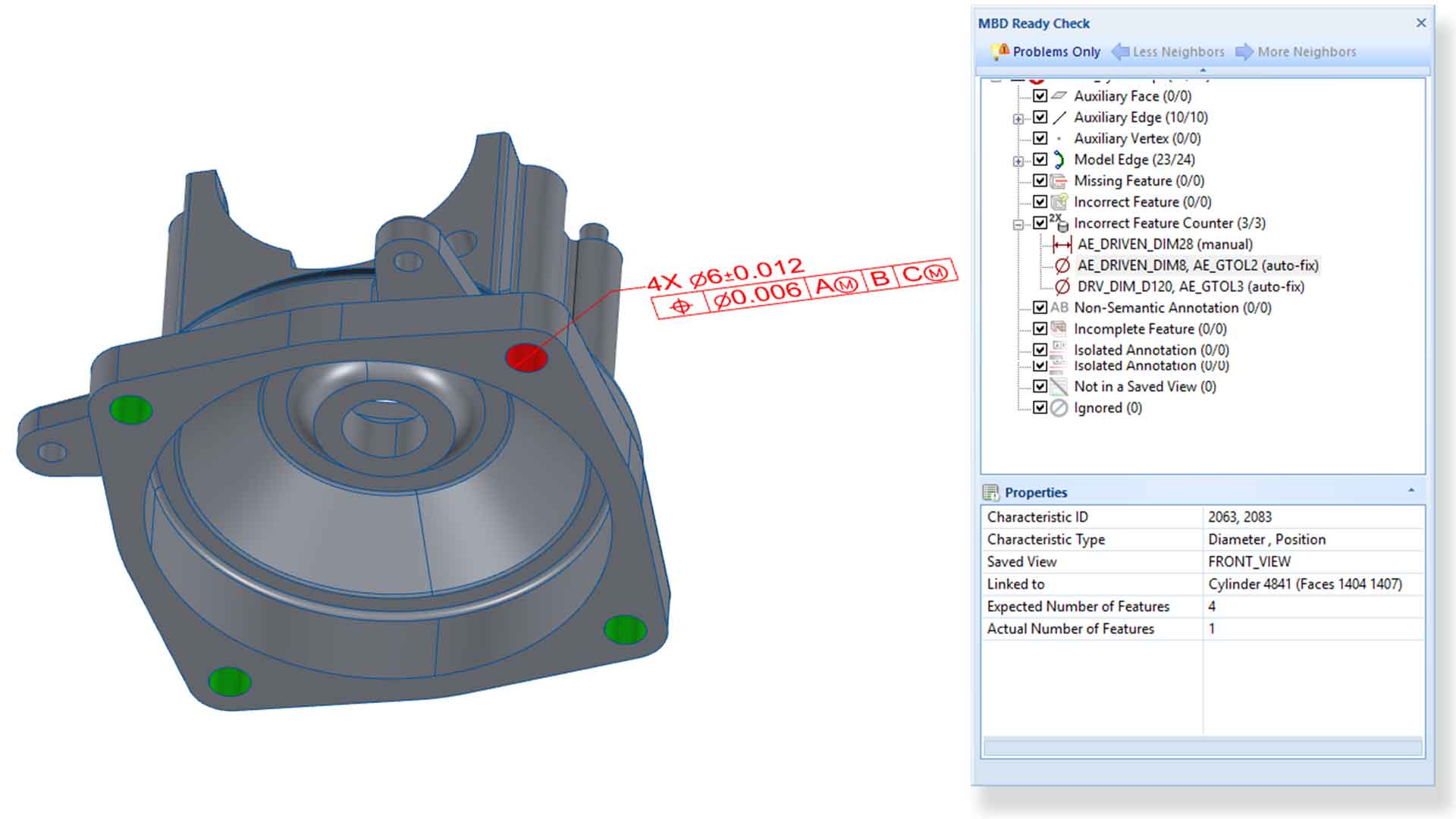

With MBD ready check, make sure your PMI is machine readable to drive downstream automation.

Stop manually entering GD&T- automation saves time & money.

Free from human reading, typing, and validation errors.

Capvidia is your partner and source for the best MBD practices in Industry 4.0.

We're the ground-floor, roll-up-your-sleeves company, so we work directly with CAD engineers & designers as they transform their work, department, or company into MBD/MBE.

Personnel focus. Process focus. ROI-driven focus.

Our MBD specialties:

Some sell software, others sell services. We provide solutions, period. From CAD to CAD, CAM, CAE, CMM, and other software, we assist you in getting complete file interoperability throughout the process– most importantly, RESULTS.

When you call or email us, we’re fast to respond. It’s always nice to have a Robin to your Batman, right?

We are partners with major CAD vendors to ensure consistent performance of MBDVidia 24/7. We’re always current & on top of the latest trends.

QIF and STEP AP 203, 214, and 242.

No, FormatWorks does not generate inspection forms. MBDVidia is a standalone software that does this.

FormatWorks allows for exporting in QIF and STEP AP242.

MBDVidia is a standalone software that exports QIF and STEP AP242 and also MBD workflows such as MBD first article inspection and PMI healing.

Model-based definition (MBD) is the practice of embedding 3D annotations aka semantic PMI into the 3D model itself. It's the next evolution as the industry transitions away from 2D drawings and into human & machine-readable 3D models.

Software | Services | Support | Projects

Capvidia focuses on true MBD workflows: 3D CAD translation & validation featuring MBD CAD with semantic PMI that is human & machine-readable for downstream use from design to manufacturing.

With one single source of truth, interoperable data is shared among different teams, partners, and personnel with their current systems (CAD, CAM, CMM, etc.) powering automation, AI, and Big Data insights.

We've been trusted for over 26 years pertaining to all things CAD software.

How can we help you?