Get full DPD requirements approval for Boeing D6-51991, Airbus, Lockheed Martin, ULA, Northrup Grumman, etc.

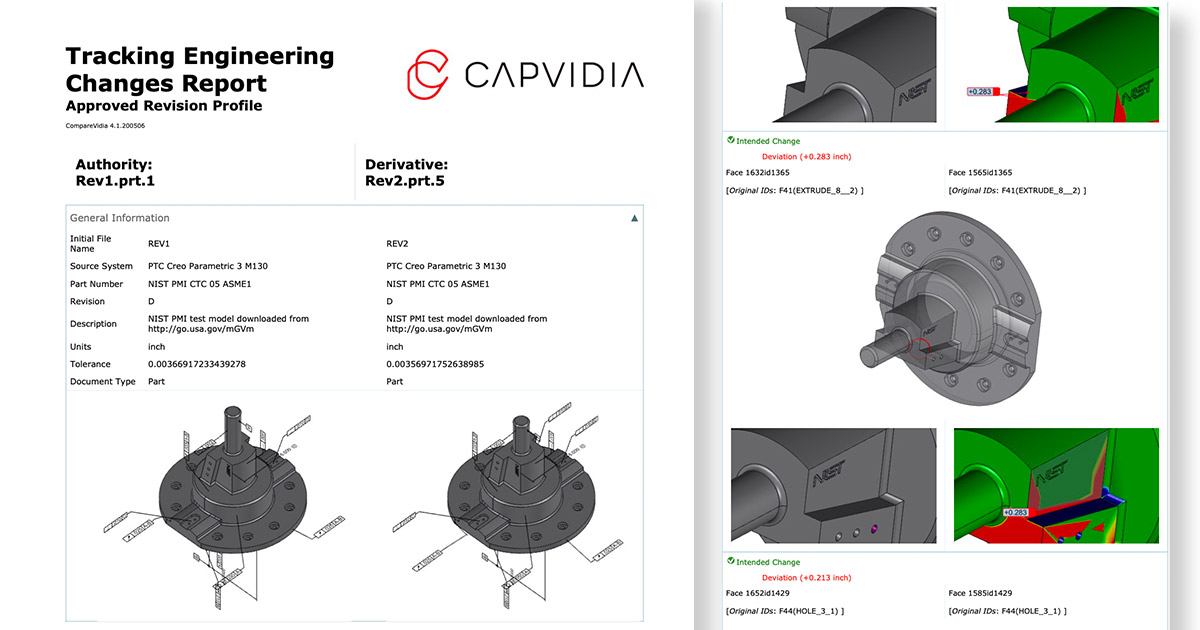

Compare different revisions to detect intended & unintended changes.

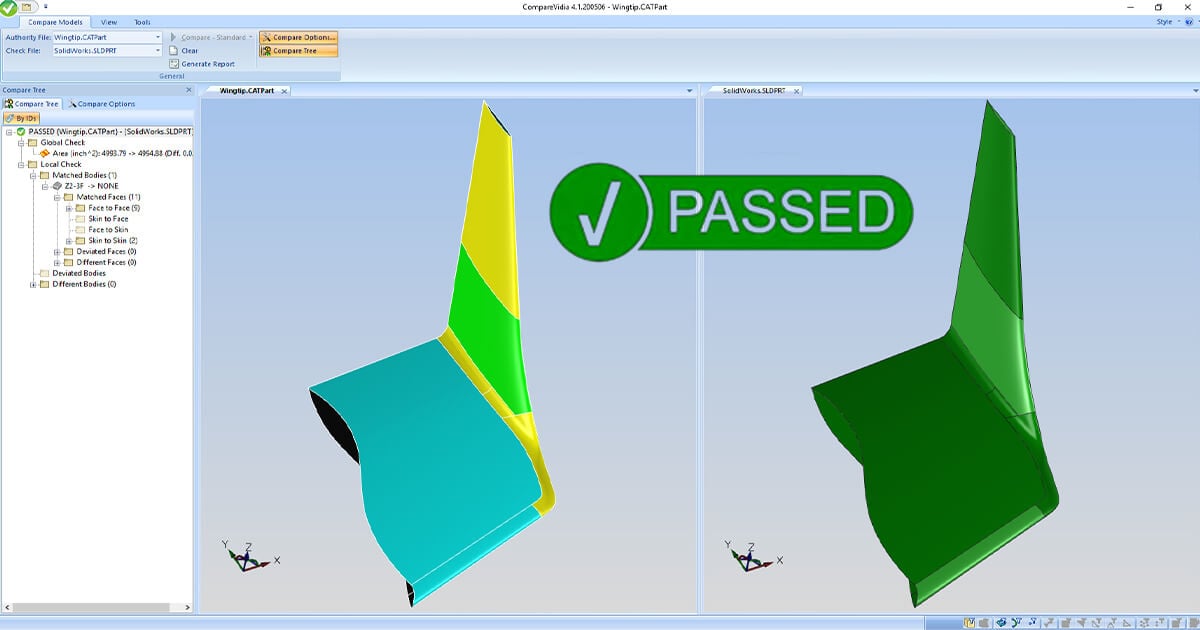

Confirm that derivative models match the native source model.

Load any 3D CAD model and check the derivative against the authority model. B-rep, point-cloud, and mesh–all acceptable.

Compatible with Creo, SolidWorks, NX, CATIA, Inventor, QIF, STEP AP242, IGES, STL and more.

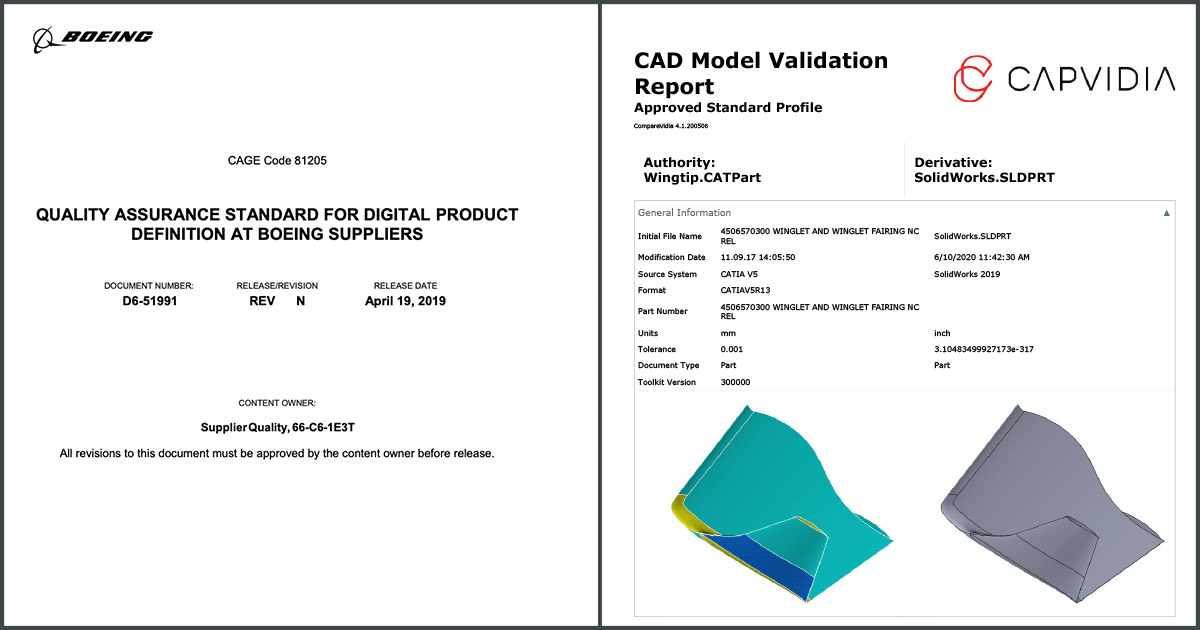

Adheres to Boeing D6-51991 Quality Assurance Standard for Digital Product Definition at Boeing Suppliers and other aerospace standards for Airbus, Lockheed Martin, United Launch Alliance, Northrup Grumman, and more. In a few easy steps, you get a validation report that you can present to your auditor.

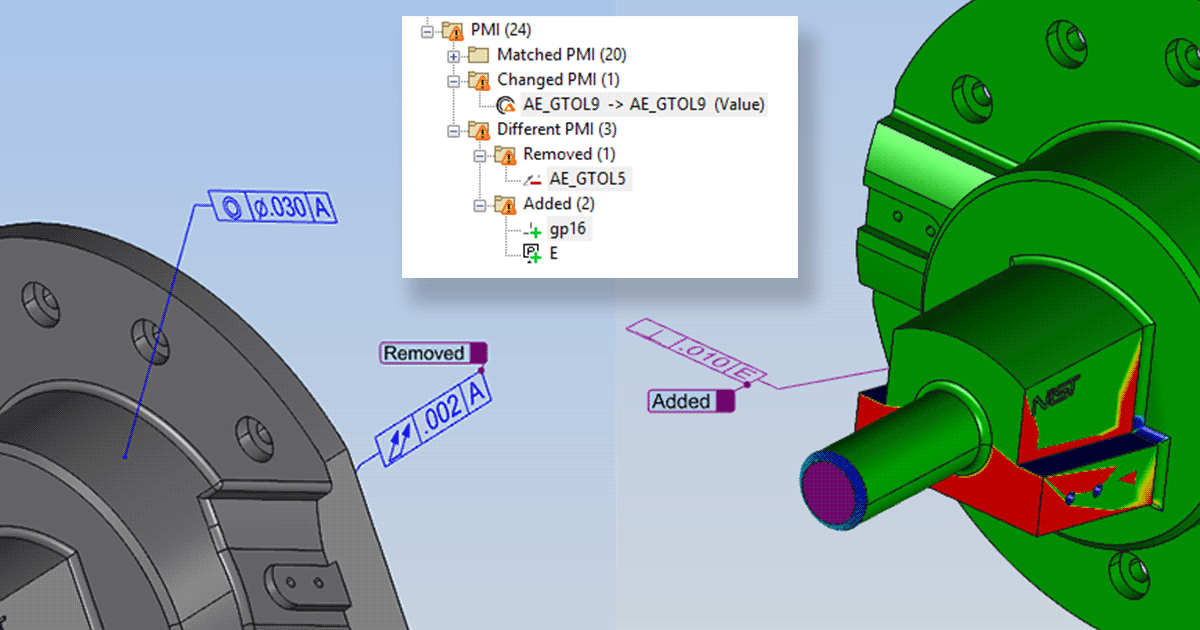

Compare GD&T, notes, and 3D annotations that are machine-readable for MBD use.

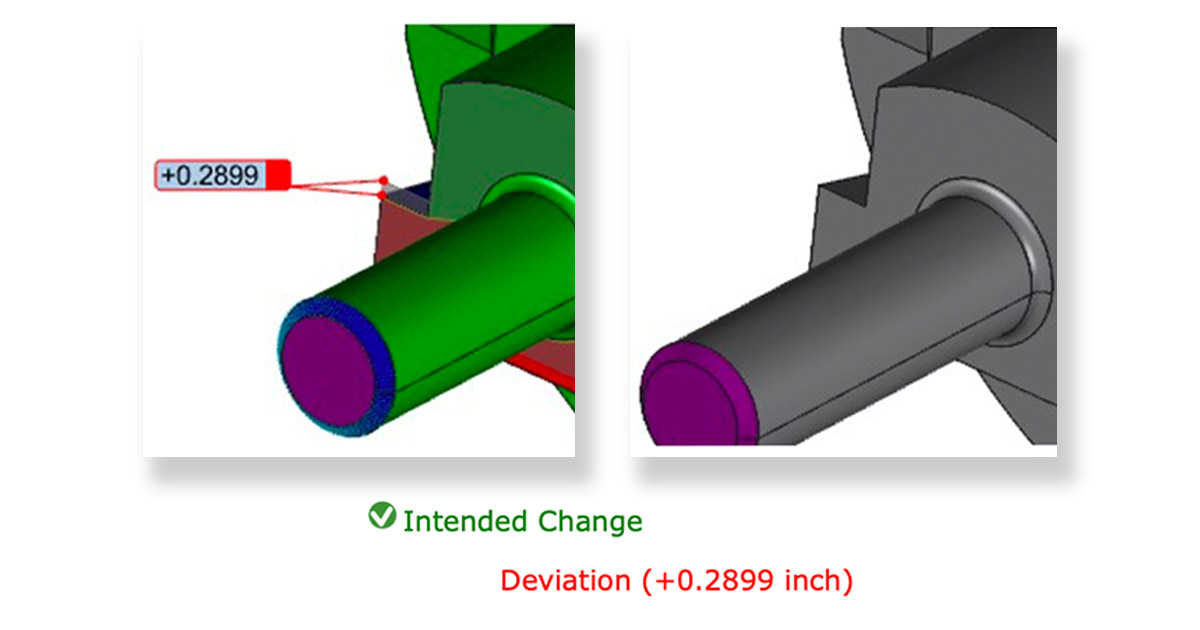

Compare two revisions of a CAD model. Mark any changes as “Intended” or “Unintended.”

Digitally certified pass/fail reports inspecting CAD geometry, PMI, assembly structure and more.

Rely on an automated, structured process, and simple workflow.

Validate your CAD model integrity at different stages of the digital product lifecycle.

Detect and identify even the smallest of changes or errors in geometry, topology, and annotation (including PMI).

Capvidia is the thought leader in MBD and PMI with the leading manufacturers, suppliers, and companies trusting our tools & process.

Match and validate any two CAD models with ease with pass/fail reporting.

Satisfy auditors from high-value manufacturers like Boeing, Lockheed Martin, United Launch Alliance, Northrup Grumman, and more with a well-controlled CAD translation process.

Capvidia is your partner and source for the best MBD practices in Industry 4.0.

We're the ground-floor, roll-up-your-sleeves company, so we work directly with CAD engineers & designers as they transform their work, department, or company into MBD/MBE.

Personnel focus. Process focus. ROI-driven focus.

Our MBD specialties:

Some sell software, others sell services. We provide solutions, period. From CAD to CAD, CAM, CAE, CMM, and other software, we assist you in getting complete file interoperability throughout the process– most importantly, RESULTS.

When you call or email us, we’re fast to respond. It’s always nice to have a Robin to your Batman, right?

We are partners with major CAD vendors to ensure consistent performance of MBDVidia 24/7. We’re always current & on top of the latest trends.

Yes to all.

CompareVidia can support comparison of mesh to mesh, mesh to b-rep, or mesh to point cloud.

It's the leading tool for analyzing PMI and MBD CAD models.

Software | Services | Support | Projects

Capvidia focuses on true MBD workflows: 3D CAD translation & validation featuring MBD CAD with semantic PMI that is human & machine-readable for downstream use from design to manufacturing.

With one single source of truth, interoperable data is shared among different teams, partners, and personnel with their current systems (CAD, CAM, CMM, etc.) powering automation, AI, and Big Data insights.

We've been trusted for over 26 years pertaining to all things CAD software.

How can we help you?